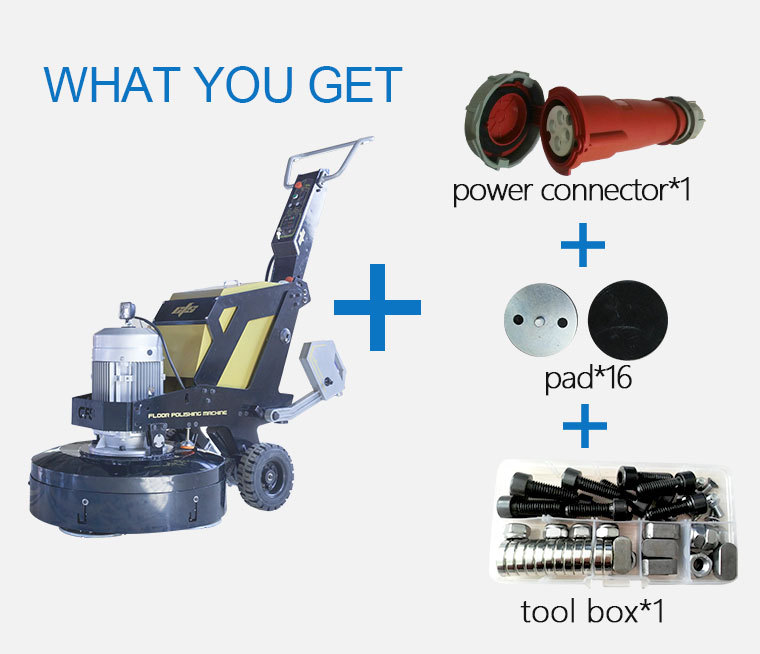

Search This Supplers Products:R&D,production , construction, training, export salesR&D, production and sales of floor grinder machinesprovides concrete floor hardening repair of factory buildings, warehouses, sealing and curing floorsmainly provide floor construction products such as floor grinder machine, polishing pad, etcindustrial vacuum cleaner, concrete seal curing agents, high permeability super cement curing agent

KD-850 Planetary Concrete Grinder

- group name

- Concrete Grinder Machine

- Min Order

- 1 piece

- brand name

- KAIDA

- model

- KD-850

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram

- update time

- Tue, 21 Jan 2020 13:30:01 GMT

Paramtents

Power 20hp(15kw)

Inverter 15kw

Voltage 380V-420V

Frequency 50HZ

Rotating speed 300~1500rpm

Packging & Delivery

- 210cm x70cm x107cm

-

Min Order1 piece

Briefing

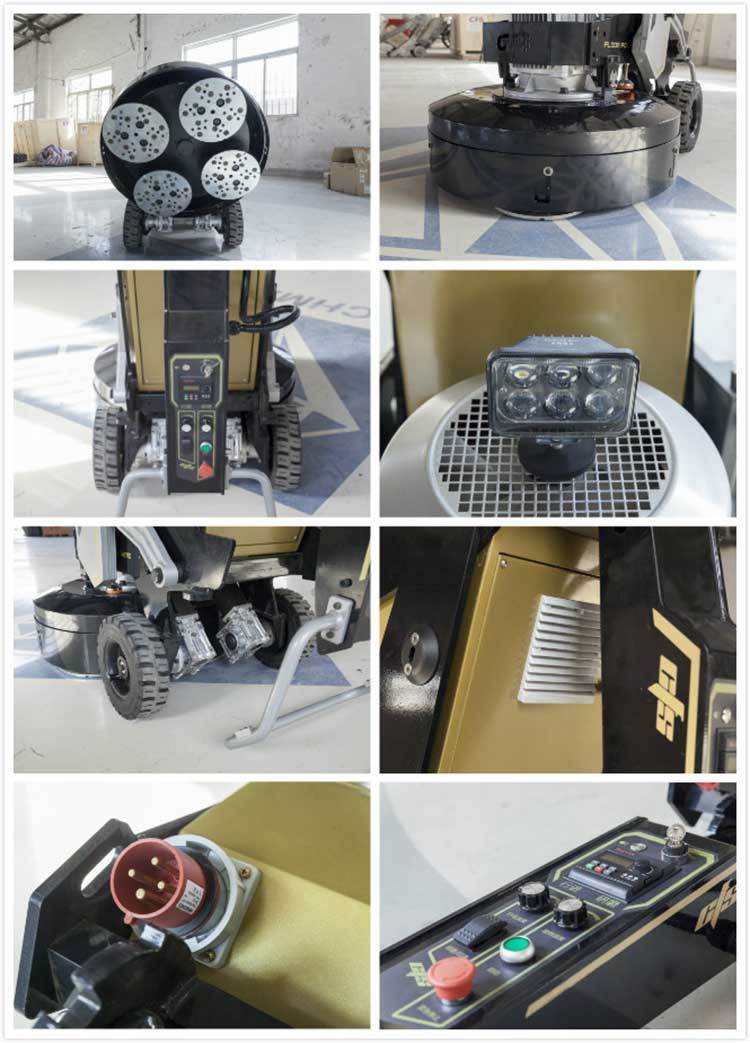

Four grinding discs adopt gear-to-turn transmission design.

Detailed

Product/User Benefits:

Increased productivity and grinding performance

Easy handling thanks to ergonomic control elements, fixed speed as well as low noise and vibration levels

Fatigue-proof working and reduction of side forces because of outstanding machine balance

Maximum durability and load capacity due to very robust construction

Impressive mobility as well as trouble-free transportation thanks to detachable machine parts

Time saving patented quick tool fixing system

Dust-free operation because of floating cover in combination with reliable dust collection system

Fields of applications:

Grinding concrete/epoxy floor/ solidified floor/ terrazzo floor /granite floor /natural marble floor /diamond abrasion resistant floor /self leveling cement,etc ,places requiring surface treatment

Removal of paint, epoxy, glue and other coatings from concrete

Preparation of concrete for installation of new flooring/coating

Elimination of irregularities in concrete

Repair of damaged concrete

Sealing preparation

Renovation works

Product Features:

1.Four grinding discs adopt gear-to-turn transmission design

2.The main plate and the planet disk are driven independently to ensure the flatness of the ground

3.Ground grinding can estimate the workload of one day and facilitate the development of construction plans

4.One-button cruise control, drive control system automatically walks, liberating labor safe and efficient

5.Set parameters to ensure the working speed of the grinder and the stability of the grinding pressure to achieve precise grinding

6.Integrated integrated control system design, with universal wheel system, reducing labor intensity and improving construction efficiency

7.Large industrial vacuum cleaner can be configured to achieve dry and wet floor grinding mode

8.Set the walking speed of the grinder to realize the ramping of the up and down slope

9.One-piece laser cutting aluminum alloy gear box, the device weight 588KG achieves fast and efficient grinding

10.Intelligent technology dust-free grinding, responding to the strategic layout of national environmental protection policies